In modern architecture and construction, doors and windows are more than just functional elements for protection — they are key factors that define a building’s aesthetics, durability, and energy efficiency. Choosing the right material for the profile frame is a strategic decision.

Among materials like wood, aluminum, and plastics, PVC Compound is emerging as a superior solution. Why is it trusted by both manufacturers and informed consumers? Let’s explore the key reasons with Green PVC.

1. Outstanding Durability & Weather Resistance

This is the number one reason why PVC Compound dominates the market. Profiles made from this material can withstand the harshest environmental conditions without losing their quality.

- Long service life: Unlike wood, which is prone to rot and termites, or metal, which corrodes and rusts, PVC Compound is completely resistant to decay, rust, and corrosion.

- UV resistance: With optimized formulation, PVC profiles resist UV damage, maintaining their color and surface quality under intense sunlight — particularly suitable for tropical climates.

- Weatherproof: Whether facing heavy rain, high humidity, or sudden temperature changes, PVC profiles remain free from warping, shrinking, or deformation.

2. Superior Mechanical Strength

A good door and window system must remain strong and secure throughout its lifespan — and PVC Compound meets this requirement perfectly.

- High impact resistance: Prevents cracks and breakage during transportation, installation, and daily use.

- Excellent dimensional stability: Profiles maintain their exact shape and size over the years, ensuring smooth operation and a tight seal.

- Strong screw retention: Hinges, locks, and handles can be mounted securely for long-lasting safety and reliability.

3. Cost & Production Efficiency

For manufacturers, economic efficiency is crucial — and PVC Compound delivers a clear competitive advantage.

- Lower production cost: Compared to aluminum or wooden profiles, producing PVC Compound profiles via extrusion is significantly more cost-effective.

- Efficient production: PVC Compound offers excellent melt flow and fusion, ensuring smooth extrusion and consistent product quality.

- Low die build-up: This reduces machine downtime for cleaning, increasing productivity and output.

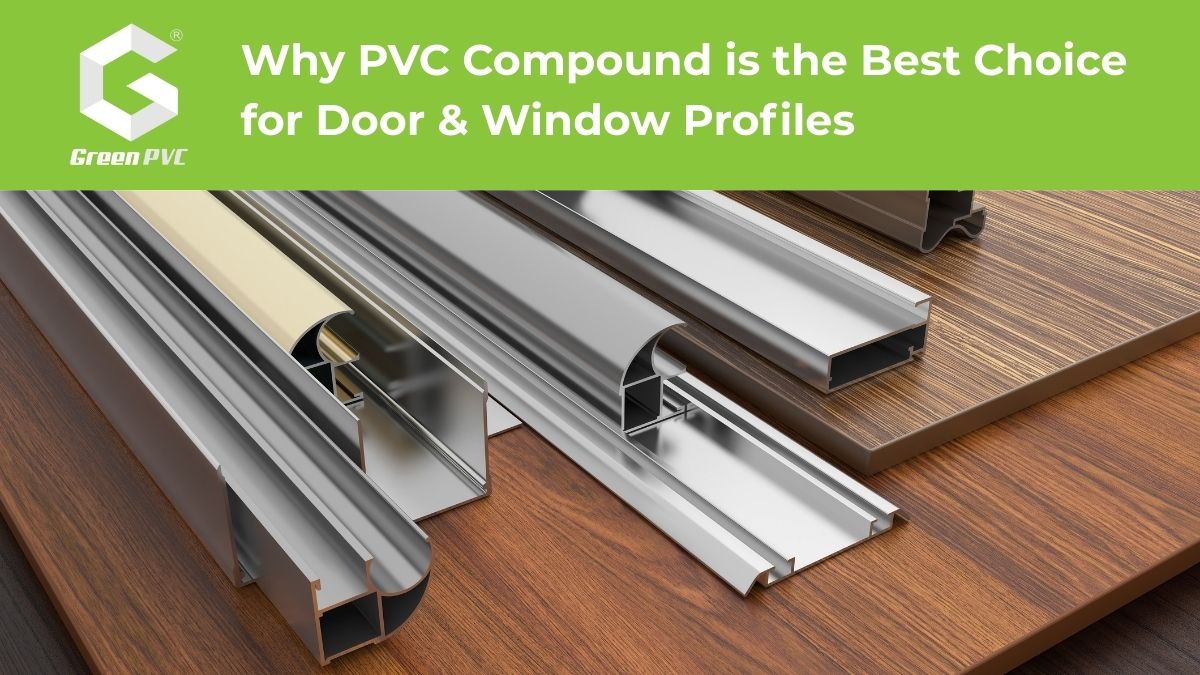

4. Design Flexibility

Aesthetics play an important role in modern construction, and PVC Compound provides limitless design possibilities.

- Wide range of colors and finishes: From glossy to matte, and even luxurious wood-grain laminates — adaptable to any architectural style.

- Custom formulations: Tailored to meet specific climate conditions or special performance requirements.

5. Sustainability & Safety for the Future

With the rising importance of green manufacturing and environmental safety, modern PVC Compounds are designed to meet strict standards.

- Health & safety: Premium products use lead-free stabilizers, meeting global environmental requirements such as REACH and RoHS.

- Recyclable: PVC is 100% recyclable, helping reduce waste, conserve resources, and support a circular economy.

Green PVC – Premium PVC Compound for Door & Window Profiles

Understanding these requirements, Green PVC is proud to offer PVC Compound for Door & Window Profiles — a comprehensive, high-quality solution for manufacturers.

Our products are developed to optimize all these outstanding benefits:

- Excellent UV resistance and long-lasting color stability.

- High mechanical strength and superior impact resistance.

- Stable production processes with exceptional efficiency.

- Lead-free, export-compliant formulations.

Choosing Green PVC Compound means more than selecting a raw material — it means partnering with a reliable supplier committed to your long-term, sustainable growth.

With the perfect combination of durability, cost efficiency, design flexibility, and eco-friendliness, PVC Compound is the ideal answer for door and window profile materials in the modern era.

📩 Contact us today to learn more about PVC Compound for Door & Window Profiles and get expert consultation for your production needs!