In Vietnam’s expanding Wire & Cable market, local manufacturers face a dual challenge: how to maximize performance from existing machinery while ensuring the highest level of final product quality. For one of our clients, a residential cable manufacturer, this was not just a technical puzzle but a direct threat to their profitability and market reputation.

I. The Challenge: A Two-Front Battle – Performance Limits and Technical Flaws

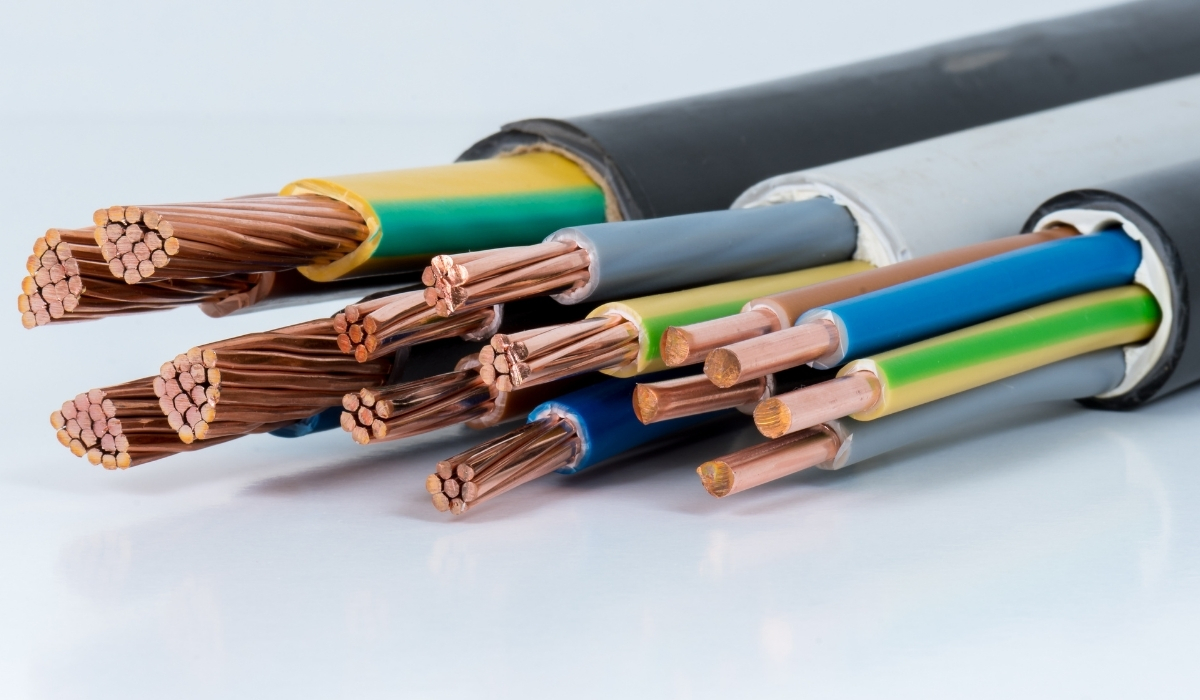

Our customer was restricted to an optimal extrusion speed of approximately ~15m/minute. Crucially, they were using imported plastic granules that were incompatible with their existing extruders (old 45–65mm machines, running at 60–70% capacity). When attempting to run faster, the previous PVC compound’s poor thermal stability caused severe surface defects like pitting or uneven melt flow.

This situation created major business consequences:

- High Hidden Costs: A daily scrap rate of 3–5% wasted material and electricity, while continuous machine shutdowns increased labor and maintenance expenses.

- Reputation Damage: The lack of lot-to-lot consistency led to complaints from distributors and project contractors.

II. The Technical Solution: A Methodical Approach to Custom Formulation (GVC-6012)

Instead of offering a generic solution, the Green PVC R&D team acted as a technical partner, focusing on the root cause. After surveying the client’s actual cable extrusion setup, we determined that the key lay in optimizing the material’s thermal stability and flow characteristics.

Green PVC developed and proposed the PVC Compound GVC-6012 (specifically designed for 300/500V residential soft cable). This customized formulation was engineered to:

- Ensure High Thermal Stability: Tightly control viscosity and melt flow, eliminating pressure fluctuations at the die head.

- Reduce Extrusion Pressure: Allow the existing, older extruder to run smoother and more consistently without overload.

III. Performance Analysis: Driving Productivity & Lot Quality Stability

The transition to the GVC-6012 PVC Compound delivered a measurable transformation in operational efficiency. The client achieved the following quantifiable improvements:

| Technical Performance Metric | Previous PVC Compound | GVC-6012 PVC Compound (Green PVC Solution) | Achieved Improvement |

| Optimal Extrusion Speed | ~15 m/minute | ~25 m/minute | Increase 60% Machine speed gain |

| Surface Defects (Pitting/Uneven) | Frequent | Virtually eliminated | Better flow control and die compatibility |

| Machine Downtime/Maintenance | High | Significantly reduced | Increased production efficiency |

| Product Standard | Unclear | Meets TCVN 6610-3:2010 (equivalent to IEC 60227-3) | Guaranteed outbound quality standard |

Overall Business Impact: Due to stable speed and reduced defects, the client achieved 30–40% overall production volume growth.

Green PVC helped the manufacturer turn a technical challenge into a competitive advantage, securing their position as a trusted local supplier of quality cables.

Contact us to have a detailed TDS and schedule a direct consultation with our R&D team to optimize your production line.